Backplates and bellhousings - marrying engines to gearboxes

A question I am asked quite often is “will X engine bolt up to Y gearbox?” Land Rover used only four basic designs for engine / gearbox interface between 1948 and 1998 and there is a fair bit of compatibility between engines and gearboxes of different ages. All the engines apart from the V8 used a bolt-on cast alloy flywheel housing at the back of the engine, and these can sometimes be swapped between engine types. Series gearbox bellhousings are interchangeable to some extent as well. Here are the main things you need to know.

Engine stud pattern: this breaks down into four main groups:

Pattern A: Series inlet over exhaust engines (Series One, early Series II 88 petrol, and 2.6 litre straight-six Series IIA / III): these all share the same stud pattern with studs either side of the 12 o’clock position on the flywheel housing but no stud at 12 o’clock.

Pattern B: Four cylinder OHV engines 2.25 / 2.5 (Series II/IIA/III, 90/110/Defender to end of 200TDi production): stud at 12 o’clock position, identical pattern for Series and coil sprung vehicles with the LT77 gearbox, except the LT77 has one stud left out (around eight o’clock) to make room for the clutch slave cylinder.

Pattern C: Discovery / Range Rover Classic 200 / 300TDi: most of the top half studs in the same place as a Defender, but bottom half is completely different. 200TDi has four long through bolts going into the block stiffener, 300TDi uses short bolts into the flywheel housing in the same place. Discovery 200TDi and 300TDi gearboxes share the same bellhousing stud / bolt pattern and have two steel dowels for accurate alignment.

Pattern D: V8: totally different, with UNC bolts attaching the bellhousing direct to the engine block, no studs or bolts below the bottom of the block, starter on opposite side of engine to all the others.

Gearbox bellhousings: several different versions. We’ll break it down into Series, LT77, R380 and V8 gearboxes

Series gearboxes

Series One and early Series II, 1.6/2.0 IOE engines: pattern A, small layshaft bearing, cross-shaft holes both sides

Series II / IIA (early): pattern B, small layshaft bearing, cross-shaft holes both sides

Series IIA (late) 4 cylinder: pattern B, large layshaft bearing, cross-shaft hole offside only

Series IIA (late) 6 cylinder: pattern A, large layshaft bearing, cross-shaft hole offside only

Series III (4 cylinder): pattern B, large layshaft bearing, clutch slave cylinder mounted to bellhousing

Series III (6 cylinder): pattern A, large layshaft bearing, clutch slave cylinder mounted to bellhousing

Bellhousings with the small layshaft bearing cannot be fitted to gearboxes designed for the large bearing. The layshaft and clutch release housing are both different. Otherwise bellhousings are pretty much interchangeable: 6 to 4 cylinder, Series IIA to III or vice versa. Obviously if you are fitting a Series III bellhousing to a IIA gearbox you will need to replumb the clutch system to suit the Series III slave cylinder which is the opposite side of the gearbox to a IIA.

LT77 5-speed

90/110, 2.25, 2.5, 200TDi: pattern B, short input shaft, large spigot bush

90/110/Range Rover V8: pattern D, long input shaft, small spigot bush

Discovery / Range Rover 200TDi: pattern C, long input shaft, large spigot bush

No real interchangeability here due to the different input shaft lengths. You can swap the input shaft to match a longer or shorter bellhousing but that means dismantling the gearbox. Likewise you can swap between “long stick” (90.110, early Range Rover) and “short stick” (Discovery, late Range Rover) but only if you change the selector shaft which again is a full gearbox strip job.

R380 5-speed

Defender / Discovery / Range Rover 300TDi: pattern C, long input shaft, large spigot bush

Discovery / Range Rover V8: pattern D, long input shaft, small spigot bush

Defender “stumpy” (military spec): pattern B, very short input shaft, large spigot bush.

Again no real interchangeability, but note than converting an R380 from short to long stick can be done with a bolt on kit from Ashcroft, so an ex Discovery gearbox will go into a Defender 300TDi. Note also that the R380 is slightly longer than an LT77: for the Discovery and Range Rover the bellhousing was shortened accordingly. So a Discovery R380 gearbox can be fitted to a Discovery / RR 200TDi in place of an LT77 and will bolt straight up to the engine, but you will need to use the R380 bellhousing.

V8s

90/110 V8: earlier vehicles used the LT95 4-speed, later ones the LT85 5-speed. Neither of these can be bolted to any engine other than a V8 without using an adapter ring, made by various companies including Milner and M&D over the years. A few very late military / export V8s used a long-stick LT77.

Range Rover Classic (early) / 109 V8 / 101FC used the LT95 gearbox, same applies. People have bolted all kinds of engines to these gearboxes over the years from old Perkins lumps to Chevy V8 diesels, but you will need an adapter to suit.

Flywheel housings

The main issue here is when people want to use ex Discovery 200 / 300TDi engines (pattern C) to replace the old four cylinder 2.25 / 2.5 engines in Series or pre TDi 90/110 vehicles (pattern B). “It bolts straight on” is something you read quite a lot, but actually it doesn’t. We’ll look at 200 and 300 separately as the issues are different.

200TDi: the main issue is the four through bolts at the bottom which form part of an engineered structure designed to maintain block strength and prevent internal cracking. This was a big issue on the 2.5TD bottom end, and you can be sure Land Rover put those bolts there for a reason. On a factory Defender 200TDi the four bolts are Allen bolts recessed into the rear face of the housing, with threaded studs between them to give the standard pattern B stud layout.

As it happens, Land Rover used the same casting for the flywheel housing on several different engines but machined it differently for the various applications. I have found two casting numbers: HRC2076 (shallow recess around the crankshaft seal) and HRC2165 (no recess). The recess was intended to be filled with RTV sealant: Land Rover fairly quickly gave up with this sealing method on the 200TDi and used a gasket instead (ERR1440). These housings first appeared on the 2.5 NA and TD engines around 1988, and very early ones lack the threaded hole at the bottom for a timing pin, used when replacing the timing belt. This probably doesn’t matter if you are fitting a 200TDi to a Series vehicle as the flywheel housing sits about 2cm above a chassis crossmember so there is no access for a timing pin anyway and you have to time it up by finding TDC another way, usually by removing no 1 injector and poking a long thin bar down the hole.

All these castings can be modified to Defender 200TDi pattern B specification. On 2.5 NA/TD housings you need to drill and then counterbore the four blind holes at the bottom to take M10 x 80 Allen bolts: Discovery housings also need four blind holes drilled 8.5mm and then tapped M10 to take studs or bolts, one stud removing (around two o’clock, very close to one of the blind holes that you have drilled and tapped) and the two locating dowels on the rear face removing if they didn’t come out when the engine and gearbox were separated. If all this is a bit daunting, I have been modifying these housings for about 20 years and can do yours. Contact me to arrange this.

300TDi

Although the 300TDi is the same size and power output as the 200TDi, pretty much every part of it was redesigned and that includes the flywheel housing. It has the rear crank seal in a separate cast aluminium carrier rather than being pressed into the flywheel housing: and as Land Rover dropped the LT77 gearbox when the 300TDi came out, the new flywheel housing was designed to only cater for stud pattern D. This creates some problems when bolting up a 300TDi to a Series or LT77 ‘box: there are four missing studs in the lower half, and not enough metal in the casting to take them all. There is one blind hole at the 6 o'clock position which can be drilled and tapped for an M10 stud, but that’s all. The photo below shows a 200TDi (pattern B) flywheel housing on the left, 300TDi on the right.

200TDi (left) and 300TDi (right) housings compared

If you’re bolting your 300TDi into an older 90 or 110 I wouldn’t worry too much about the missing studs. Most modern vehicles only have four or five studs / bolts attaching the engine to the gearbox: an LT77 in a Defender has eleven. That’s more than enough. Things are trickier in a Series. Firstly the flywheel housing has two lugs extending outwards to the bottom which bolt to a pair of braces running back from the engine mounts. On a Series these foul the crossmember under the flywheel housing, so they have to come off. Secondly, one of the missing studs is where the clutch release bracket bolts to the bellhousing on a Series II / IIA, which isn’t ideal.

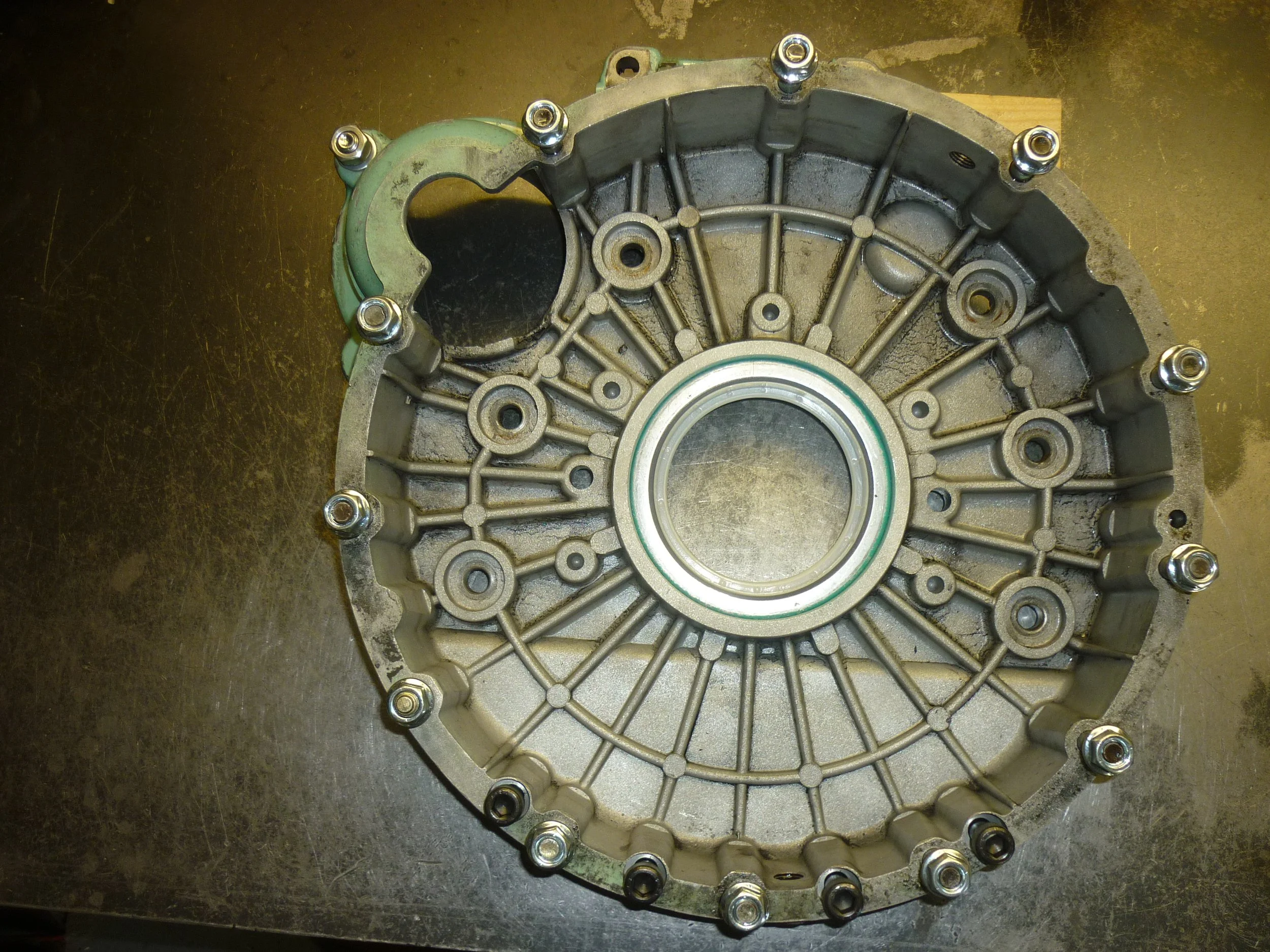

The easiest solution here is to acquire a flywheel housing from an older 2.5 or even 2.25 diesel (as long as it has the five bearing crankshaft: three bearing engines have a totally different design of crank seal). Cut off the diagonal bracing straps from the engine mounts, remove the 300TDi rear crank seal and carrier, partly drill out two of the housing-to-block bolt holes 15mm from behind to clear the hollow dowels in the block, and fit the flywheel housing using a new crankshaft seal ERR2532 pressed into the housing, and a bead of RTV sealant to seal the housing to the block. (Early housings use a large O-ring to seal them to the block.) The 2.25 / 2.5 housings come in various flavours: most 2.25 housings have Imperial studs, housings up to around 1985 have a timing window and pointer for setting up the pump timing, and only the later 200TDi-type housings have the threaded hole at the bottom for a timing pin. Pre-TDi engines are timed differently and have a threaded hole near the top of the housing which is of no use at all when timing a TDi. As noted above you can’t insert the bottom timing pin into a TDi in a Series vehicle anyway so it doesn’t make much odds. The older style of housing (photo below) are cheap as chips and readily available. The example below has the O-ring seal, later ones lack this.

Obviously you lose the diagonal braces but that is always going to be the case anyway in a Series unless you start cutting and welding the crossmember under the flywheel housing. I don’t know what purpose those braces serve: whether they were put there to stop the flywheel housing flexing and cracking, to get rid of an unwanted vibration that turned up in early tests, or to stiffen up the block itself. I’m not aware of anyone having had issues after removing the braces, but if I was putting a 300TDi into a 90/110 with an LT77 box I’d keep the 300TDi flywheel housing and braces just to be on the safe side.

Early 2.5 diesel flywheel housing, front and back

Adapters: over the years people have put pretty much any diesel engine into a Land Rover that will physically fit, and a few petrols as well. A few companies made adapter plates or rings for various conversions: Milner, Philips, Steve Parker and M&D are the main names that come to mind. If you are buying one of these second hand, check the stud pattern carefully. I’ve seen adapters to fit Rover V8s and Perkins 4.203s into 6-cylinder Series vehicles, and that won’t be a lot of use to you if you’re swapping out a 2.25 diesel. Quite a few of these kits were intended to dieselise old Range Rovers and will have an LT85 / LT95 stud pattern - again, not a lot of use if you’re replacing anything other than a Rover V8. Buyer beware…

If you have found this information useful, please consider supporting my work (and encouraging me to keep writing technical Land Rover stuff and putting it on the Internet) by buying me a virtual coffee here.